Products

Search

Product Categories

message

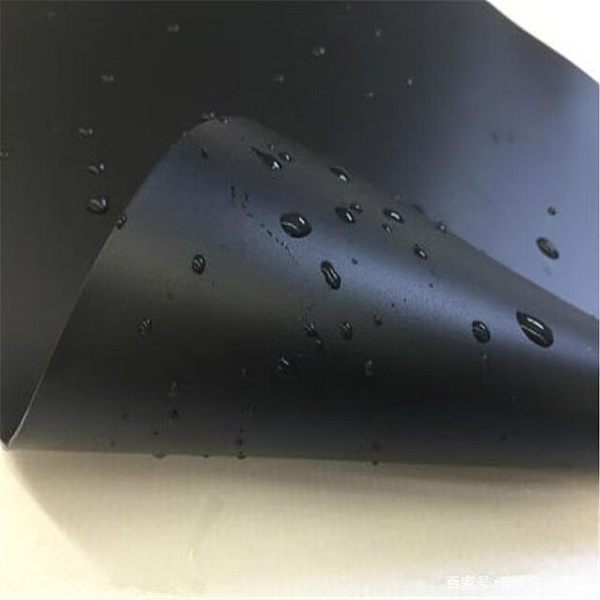

HDPE roughened geomembrane is a high-performance anti-seepage material made from high-quality virgin high-density polyethylene resin, using a special co-extrusion blow molding or roll-forming process to create a uniformly roughened surface. Its unique single- or double-sided roughened surface significantly enhances the interfacial friction coefficient between the geotextile, soil, or gravel. It is designed for demanding engineering environments requiring extremely high anti-seepage performance and excellent slope stability.

Key Features and Benefits

Excellent Anti-Slip Stability: The roughened surface creates an excellent friction interface, effectively preventing the cover material from slipping on steep slopes, ensuring the long-term stability and safety of the entire liner system.

Excellent Anti-Seepage Performance: Inheriting the inherent low permeability of HDPE, its permeability coefficient is extremely low (≤10⁻¹³ m/s), forming a strong and durable fluid barrier that effectively blocks the migration of pollutants, liquids, and gases.

Excellent Physical and Chemical Durability: It exhibits extremely high tensile strength, tear resistance, and puncture resistance. It also offers exceptional chemical resistance, resisting corrosion from most acids, alkalis, salts, and organic solvents, making it suitable for harsh landfill and industrial environments.

Excellent UV and aging resistance: The addition of high-quality carbon black and antioxidants provides strong UV resistance, maintaining long-lasting material performance and service life even under outdoor exposure.

Strong environmental stress cracking resistance: High-quality HDPE raw materials ensure excellent resistance to environmental stress cracking, maintaining structural integrity even under long-term loads.

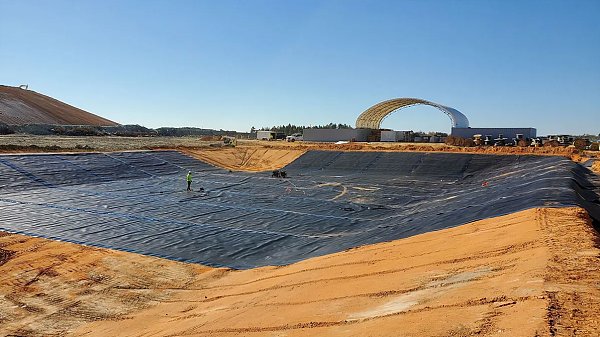

HDPE Geomembrane Textured Application

HDPE Geomembrane textured is used in applications that require increased frictional resistance, excellent chemical resistance and endurance properties such as solid waste landfills, hazardous waste landfills and C & D Landfills, mining, coal ash pond, animal waste containment, dam and embankment erosion control, artificial lake lining and so forth.

First class quality service and professional after-sales team.

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.